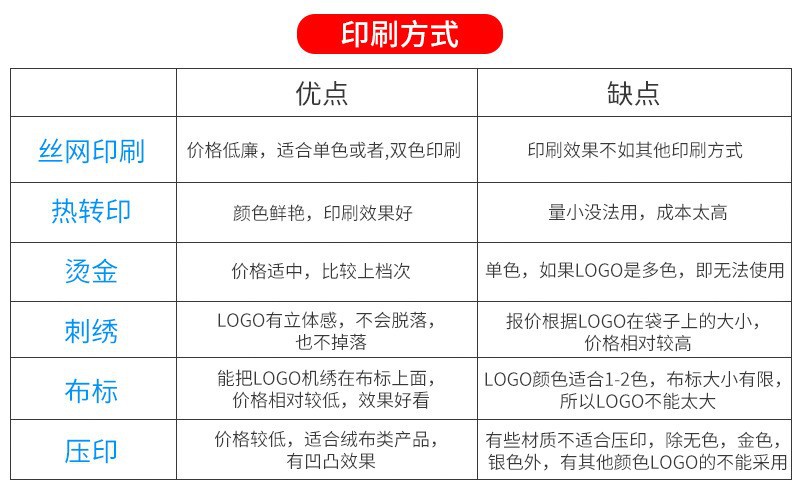

Wenzhou Junxin Packaging Co., Ltd. is a research and development. Has its own advanced production line, from printing to sewing one-stop service. Specially for domestic and foreign gift merchants, advertisers, traders and enterprises and institutions, to sample, to map batch production export as one of the processing points. Production, bag category * polyester bag * flannelcloth bag * peritoneal woven bag * Jewelry bag * Advertising bag * non-woven bag * Hat * hemp bag, drawstring bag * vest bag * mat bag, strawberry bag * Zipper bag * cotton bag, canvas bag * Oxford bag * Cotton apron * difficult bag and so on to achieve: quality assurance. Reasonable price. Exquisite service. Levy follows ". Mutual. Mutual benefit. Equality. Cooperation "cooperation principle, so that each cooperation so that each of our customers can maximize profits: so that each of our customers can save worry, labor, time to complete each cooperation. Customer's "rest assured and confidence" is the direction of our work. Have a complete and scientific quality management system. Cangnan County Longgang Junxin Luggage Co., Ltd. integrity, strength and product quality recognized by the industry. Welcome friends from all walks of life to visit, guidance and business negotiations. "Production process" is generally the use of screen printing process, that is, people commonly used printing process. Generally manual printing. Watermark because of its use of Mercury elastomeric prize as a printing medium named, in textile printing is more common, also known as printing. When printing, the color paste is mixed with water-based elastic glue. The printing plate does not need chemical solvents, can be washed directly with water. It is characterized by good coloring power. Strong covering and fastness. Washable, basically no odor. Thermal transfer is a special printing in printing. The method requires an intermediate medium, that is, the graphic is first printed on the thermal transfer film or thermal transfer paper, and then the pattern is transferred to the canvas by heating the transfer equipment. The commonly used medium in textile printing is heat transfer film. Its advantages are: fine printing. There are rich layered versions. Suitable for small area color image printing. The disadvantage is the high price and high printing cost.

Canvas bag is compared, it is taken from the natural can be degraded, that is, the cost is high and it is difficult to implement, but its durability and firmness are much higher than non-woven fabrics, from the cost is still very high, it will not cause people's criticism! Canvas: A thick fabric of cotton or hemp. It got its name from its original use in sails. Generally, plain weave is used, a small amount of twill is used, and multiple strands of warp and weft yarn are used. Canvas is usually divided into thick canvas and thin canvas two types. Thick canvas, also known as canopy cloth, commonly used 58 (10 British branches) 4 to 7 strands of thread woven, fabric fast folding, with good waterproof performance, used for car transport and open-air warehouse cover and field tent. Thin canvas warp and weft yarn is generally 2 strands of 58 to 6 strands of 28 (10 British branches / 2 to 21 British branches / 6), used for the production of labor protection clothing and supplies. After dyeing, it can also be used as shoes, travel bags, backpacks and other fabrics.